Calibrating as per the MSZ EN ISO 148-2 international standard includes the determination of the following metrological parameters:

For the determination of these metrological parameters, the device is inspected as per the following main categories:

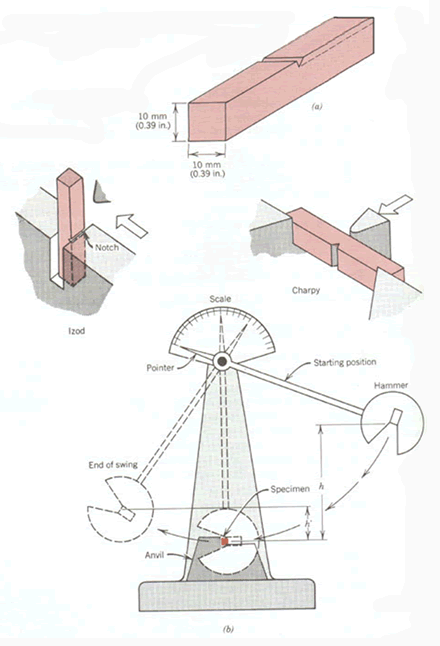

Impact tests can be distinguished by two different methods, depending on where and how the test specimen is struck.

In a CHARPY SYSTEM impact test, the test specimen, like a two-post bracket, is placed horizontally on the impactor and the pendulum strikes the side opposite the incision.

In an IZOD SYSTEM impact test, the test specimen is fixed to the machine in a vertical position as a rod clamped at one end, the incision facing the direction of impact and the pendulum measuring the impact at the protruding end of the test specimen.

IMAGE 1: Pendulum impact test

IMAGE 1: Pendulum impact test

Impact test

The results of fracture mechanics tests are used to assess the safety against brittle fracture.

We differentiate four main groups within the fracture mechanics tests:

The impact test can be used to determine the characteristics included in the first group. That is, the standardized impact-bending test can be used to determine the impact energy (KV, KU).

Impact energy is used to determine the toughness order of tough materials (e.g. stainless steels, core of hardened insert steels…).

Constant state determinants are as follows:

ambient temperature, approx. 20 C.

loading speed:

Velocity of the standardized pendulum ![]()

The stressed state is determined by the size of the specimen and the standard incision.

![]() „U” incision test

„U” incision test

![]() „V” incision test

„V” incision test

Results can only be compared if recorded with the same type of test body.